J K Steel Strips LLP has become a reliable name in the industry due to the constant efforts and dedication. Our ISO 9001:2008 certified company manufactures a line of steel coils, sheets and strips. This extensive product line comprises Carbon Steel, Spring Steel, Electrical Steel, Cold Rolled Steel, Galvanized Steel, Stainless Steel, Aluminized Steel, Coated Steel Strips, Hot Rolled Steel and more. Strip coils are handled and stored in technology & manpower equipped units situated in Maharashtras Mumbai and Taloja. The in-house testing lab facilitates continuous inspection of material at all stages in order to ensure the quality. The three processes carried out in our infrastructure include the following:

In the slitting process, larger width coils are speedily cut into narrower width coils with uniform accuracy. The process starts with fitting large steel coils onto uncoiler drum, in which the coils are uncoiled and in order to flatten them are fed through leveller. The sheets are then fed through a slitter for slitting the sheers into strips of desired width. Post slitting, the strips are passed on through tension pads/ synchro-wind rolls to give tension before the recoiling process. Recoiler is used to recoil the tensed strips to form slitted coils. The Slitting lines can slit coils with following specifications: | Parameters | Range | | Material | CR / GP / SS / HR / NO / GO / AL | | Thickness | 0.05 mm to 12.00 mm | | Width Mother Coil | 3.5mm to 1890mm | | Min Width that can be slitted | 3.5mm | | Tolerance Width | 0.10mm upto 2.00mm thk & 0.20mm above 2.00mm thk | | I.D of Slit Coils | 75mm / 135mm / 140mm / 150mm / 160mm / 220mm / 300mm/ 330mm / 400mm / 500mm / 600mm |

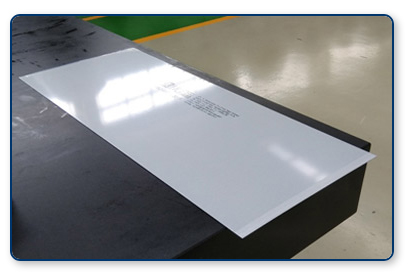

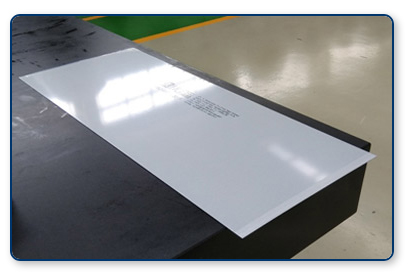

In the shearing process, the steel coils are cut into sheets/ plates in desired lengths. The process starts with the uncoiling the large steel coils by fitting the coils onto uncoiler drum. Once uncoiled, the steel coils are flattened on a leveller. The resultant sheets are cut into desired length by feeding the sheets into a motorised shear. Post shearing, the steel sheets/ plates are levelled to prevent waving effects. The sheared sheets/ plates are stacked using a stacking machine that automatically controls the sheets per stack. Our shearing machines can shear coils with following specification: | Parameters | Range | | Material | CR / GP / SS / HR / NO / GO / AL | | Thickness | 0.5mm to 15mm | | Width Mother Coil | Min 19mm to Max 2000mm | | Length | 250mm above |

The metal is coated with industrial metal coatings to add an extra protection layer against environmental and mechanical conditions. The coating can enhance the performance and working life of treated components and parts. Metal coatings are applied to steel surfaced using four commonly used methods, that are electroplating, hot-dip galvanizing, thermal spraying and sherardizing. Sherardizing and electroplating are not meant for structural steel work but are useful for fasteners, fittings and other small items. The metallic coatings can provide corrosion protection depending upon the selection of coating metal and its thickness. The protection by metallic coating is not influenced by the application method.

Hardness is not a fundamental physical property, but only a characteristic of material. It is defined as indentation resistance, and is ascertained by measuring indentation permanent depth. While using an indenter and a fixed force (load), the smaller the indentation, the harder the material. The value of indentation hardness is calculated by measuring the depth or the indentation area making use of one of more than twelve test methods.

|

Call Me Free

Call Me Free